How to Say "Yes" to Anything: M&T Printing Group Thrives with Inkjet

Family-owned M&T Printing Group—with 14 locations and 54 years in the business—is a leading print-on-demand provider in the Ontario, Canada market.

Offering a wide range of services, solutions and products, they pride themselves on being a “sales driven” rather than “production-driven” organisation. “We say ‘yes’ to everything,” said Michael Froome, M&T’s Vice President, “and then figure out a way to do it.”

“We say ‘yes’ to everything, and then figure out a way to do it.”

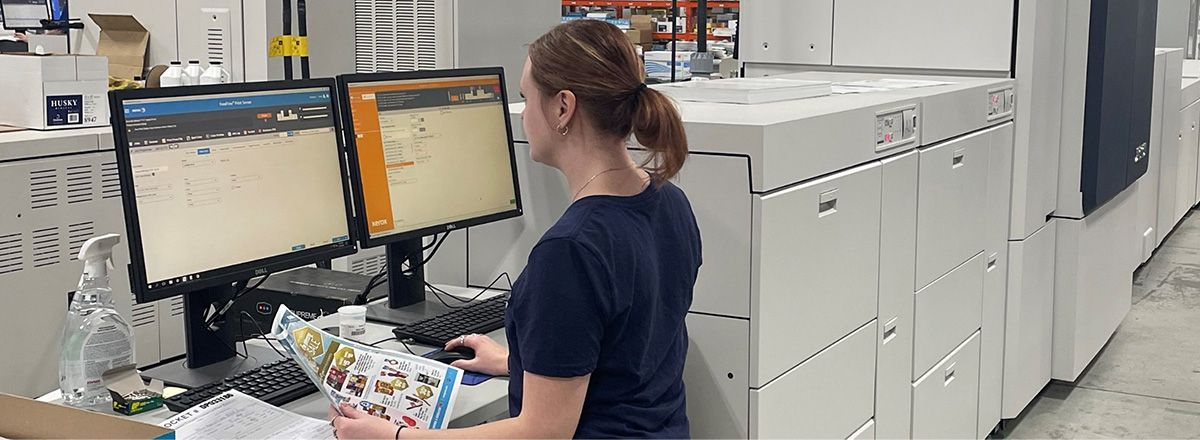

M&T offers a wide range of full-service offerings from traditional offset printing to digital production, to signage and promotional materials. Their Xerox fleet included five monochrome Nuvera® Presses, three colour Xerox® iGen® Presses, three DocuPrint™ Highlight Colour Presses (HLC), with Xerox® FreeFlow® Core workflow automation serving a key role as expediter of work across the fleet.

Moving Forward in Tough Times

M&T VP Dean Froome likens the start of the pandemic in 2020 to someone hitting the pause button on the print industry. Where some areas of their business experienced a downturn in volume, others—like large format signage, decals and floor labels—filled the gap. Being flexible enough to respond to such shifts in demand demonstrated the wisdom—and the ROI—of their diversified capabilities.

The Challenge

An Opportunity to Reset

Once things were underway again—and faced with some aging equipment—M&T saw an opportunity to enhance their production flexibility. “We need to be ready for anything,” Froome said.

A big part of optimizing for the road ahead would be addressing cost control—particularly with respect to the large volume of transactional print that passes through their shop—currently requiring offset shells and all the related storage, staffing and workflow challenges. With their offset capacity maxed out and digital demand growing, they needed to make wise investments that would allow for digital growth, while supporting offset migration/overflow.

As a “give them what they want” shop, they also recognized that a Better Together approach would address all their needs, as well as provide their customers a range of flexible cost options for the same job based on the print technology used—rather than forcing a specific job type onto a specific press. For example, some customers have higher-end colour or image quality requirements—others want the lowest cost possible.

M&T Printing Group "Must Have" Objectives

Cost Optimize

Replace HLC with full colour at comparable economics, migrate away from offset shells

Right-Size

Complement iGen 5 premium colour and Nuvera mono capabilities with lower-cost inkjet colour

Expand Capabilities

Now offering multiple options/levels of colour quality at varying price points, with faster turnaround on all job types.

Automate

Easily swap jobs between presses without engaging graphics dept

The Solution

A Better Together Approach

“We’ve trusted Xerox from the beginning,” Froome said. “Everything they’ve put in has been dynamite for our growth.” So, naturally they turned to their Xerox team for careful analysis of their needs.

The resulting plan hits on every one of their “must have” objectives—setting them up for further growth in the “roaring 2020s,” whatever they might bring.

They added Xerox® Baltoro® HF Inkjet Press with Colour Accelerator to their extensive Xerox fleet to gain the production and per-page cost flexibility they needed to stay competitive and offer a wider range of products at different price points. They also acquired an additional Xerox® iGen® 5 Press with a Xerox® FreeFlow® Print Server, a Xerox® Versant® 3100 Production Press and an inline Bourg BDFe Finisher.

COST OPTIMIZE

Migrated away from offset shells and toner-based solutions for transactional print to a one-and-done colour inkjet solution: the Xerox® Baltoro® HF Inkjet Press with Colour Accelerator.

EXPAND CAPABILITIES

Now offering multiple options/levels of colour quality at varying price points, with faster turnaround on all job types.

By adding Baltoro®, M&T has been able to:

Eliminate three HLC colour presses and migrate all HLC work to full colour with comparable economics

Complement their existing fleet with the ability to produce high quality “standard” digital colour output for up to 75% lower cost

Completely eliminate offset shells from their transactional workflow—in a way that is seamless to customers—along with the associated errors and hidden costs

Easily demonstrate cost/benefits of each technology to their customers, utilizing FreeFlow Core tools to produce proofs on multiple engines without engaging the graphics team, as well as for pre-press and job management throughout multiple locations.

M&T’s already heavy use of Xerox® FreeFlow® Core to intelligently automate workflows, balance work between presses and satellite locations, reduce or eliminate operator touches and seamlessly integrate with critical software like RSA’s MIS Print and QDirect—means they are ideally situated to get rapid results with Baltoro®.

The Results

“Give the customers what they want.”

M&T was immediately able to migrate 750K pages from the three DocuPrint™ HLC presses they eliminated to Baltoro® for comparable economics and continue to test the limits of Baltoro to find its sweet spot within their operation. They expect to migrate additional work from offset and Nuvera—as well as from iGen® 5—eventually growing volume to 3M per month.

They also see a big opportunity with their newsletter work to reduce costs by about 75% with Baltoro, as well as opportunities to gain huge efficiencies with the notepad/letterhead they currently run on offset.

According to Michael Froome, the quality between traditional offset and iGen® 5 is so close it can provide a lower-cost alternative to most offset jobs—and with Baltoro® and its Colour Accelerator, they are now able to offer a third option at an even lower price point—fulfilling their promise to let customer need drive their business—and freeing up iGen® 5 for customers requiring true offset quality.

3M

Expected monthly volume on Baltoro®

3:1

Replaced 3 existing DocuPrint™ HLC machines with 1 Baltoro®

75%

Cost savings by migrating common marketing materials to inkjet

Looking forward, Michael Froome has some advice for other print operations. “Build your business around what the customer wants,” he said.

“It’s easy to get comfortable when you have flow and volume,” he said, “but things are always changing. There was a time when every printer had their niche, but we want to be a one-stop shop—to give our customers what they want.”

4 Strategies for a More Flexible, Future-Proof Print Operation

Featured Technology

Xerox® iGen® 5 Press

Be ingenious.

Xerox® FreeFlow® Core

Automation and integration for your entire print workflow.

Related Articles

Frisco Independent School District Reconfigures for Growth with Xerox Inkjet.

Frisco Independent School District print shop adds affordable colour with room to grow with inkjet digital presses.

4 Strategies for a more flexible, future-proof print operation

The switch from offset to digital is continuing. Position your print shop for the growth in diverse, short-run jobs.

The Inkjet Opportunity

This white paper looks at how production inkjet can transform your print operations, and considerations when comparing inkjet to offset and Xerographic technologies.

Avoid these hidden costs when buying an inkjet press.

The Total Cost of Ownership of an Inkjet Press

Inkjet in Action

Real-world feedback on the Xerox production inkjet portfolio.